As I stated; been working on the cabinet for the Mirror universe project. I bought a couple of “project” Bally Star Treks from a fellow pinball collector out of Shertz a few years ago. These have been setting in storage for a while… and were very rough.

I took the cabinet with the most flaking and damage as the donor cabinet for this project. Here it is in all it glory:

I began by stripping all the hardware (coindoor) and side rails off of the machine so I could access the state of the “bones” (ie wood) of the cabinet. I noticed that the front corners were beginning to separate…. also some of the plywood cores were starting to come apart.

First I used some white gorilla glue to repair the plywood core:

Then I used ratchet straps to re-glue both sides:

I CNCed a diamond shaped piece out of MDF and glue it in the old shooter hole:

With that I began stripping the old flaking paint off with CitraStrip along the way I tried to save as much of the wood as I could. When possible; I reglued the laminate back to the plywood… or used some wood filler to fill in the rough areas.

I also repaired the bottom – not pictured. 3 of the four sides had lost the plywood under the grove… which means the bottom would probably fall out at some point. I fixed this by saving as much of the plywood core on the 1 “acceptable” side… then using quarter round pieces from Lowes. The quarter round piece was secured with the same gorilla glue and some 18 gauge pin nails.

I bought some mill wax ebony oil stain as I wanted to stain the cabinet black instead of paint. I wanted something “different” looking. Here’s one side stained with several coats. Looked like absolute trash…

That just would not do AT ALL.

The next day I went to our local WoodCraft store … they seemed to have a better selection of stain.

Since I was in new territory on this project; I decided to get a couple of product. The first was a Ebony Wood Dye product and the second was a Black Water-based Stain. The guy at the store claimed the dye would dye the fibers of the wood in a “molecular” like fashion … while the Stain is pigment based (and would act more like paint). I added the later. I figured I’d buy both and try it on the cabinet.

After I got home; I stripped the back of the cabinet and put down some test swatches:

Upper right hand: Ebony Dye

Upper LEft: Satin Black Stain

Lower Right: Stain over Dye

Lower left: 50/50% mix of both

I didn’t like the ebony stain as is… as it still had a purple/blue hue to it. The stain looked ok; but had a paint like view. The Dye under Stain had what my mind thought was the best of the two. The Dye in effect raised the wood grain a little; and the stain still let the overall look like a satin look. The 50/50 worked; but wasn’t as vibrant as the Stain over dye.

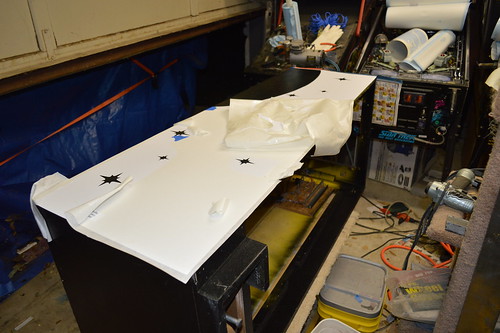

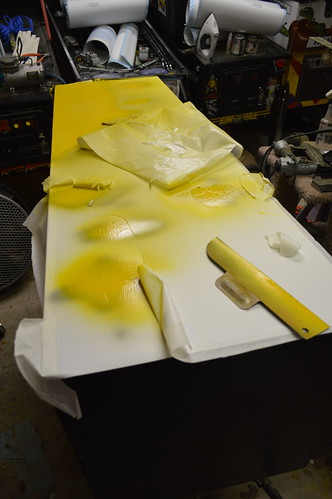

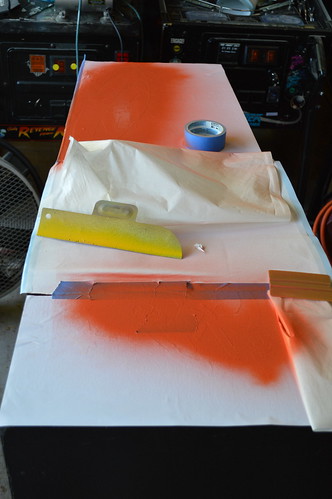

With this decision; I proceed to dye then stain the cabinet. The outsides of the cabinet were stripped of all paint; then dyed then stained. The inside of the cabinet I decided to lightly sand the interior then spray it with a Satin Black spraypaint from Rustolem. I also sprayed the bottom side with the same Satin black so it’d look more finished.

The results:

Yes… I probably could have save myself some more time by just painting the cabinet with some latex black… Or any black paint; but I kinda wanted to have the wood grains show thru the background. I may regret this decision later… but I’m currently very happy with the way it turned out.

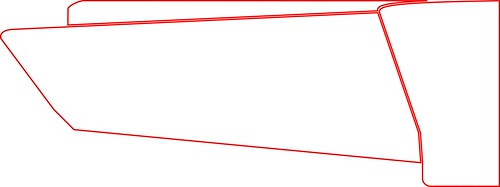

Tonight I worked on the stencil design for the cabinet. Obviously; it’s going to be a black background; however, I wanted to pay a nod to the original cabinet design. I traced the existing design and pulled it into Corel Draw. Given Black background; I still wanted to keep some of the same colors in the stencil. So the stars became Yellow. The planet Yellow/Red… and The Phasers became blue. I going to make the Enterprise BattleShip grey.

I removed the Klingons … instead having the Enterprise fire on the planet. 😀

I also worked on the front art; “inverting” the shooter location and making the color scheme similar to the sideart.

Not sure about the text at the bottom. Again limited by a stencil; but need to look at this further.

The Head: I’m thinking about keeping the Head design the same… but change the blue background to black.

After visiting with Modders-inc.com at Quakecon 2013, Lockman, MrRed, and I picked up a donor head from DonW in Garland. Don graciously donated this head to the Mirror Universe project.

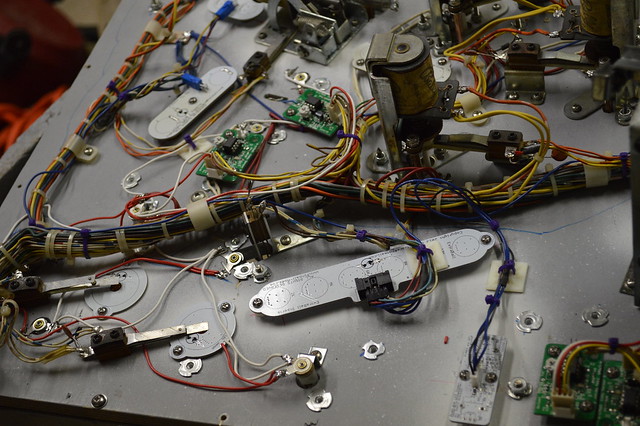

It started life as a Supersonic head… and was a rough from a paint flaking/ding perspective. All of this mattered nothing to me… as it was going to be dye/stained black just like the cabinet. Here are some before shots of the head:

The back vent hole were coming apart; good because I wanted to improve the ventilation anyway…

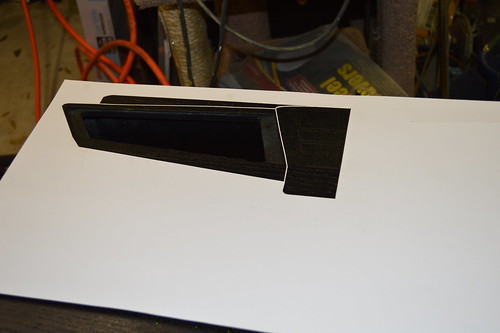

I went about destructing the head… to create new vent holes. Since eventually I plan to put more than just the original boards in the head… I decided I wanted some active cooling (IE DC FANs)… What better way to integrate vents… but using something from the Enterprise.

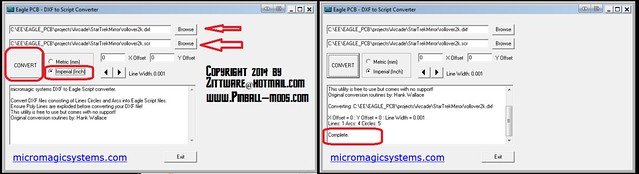

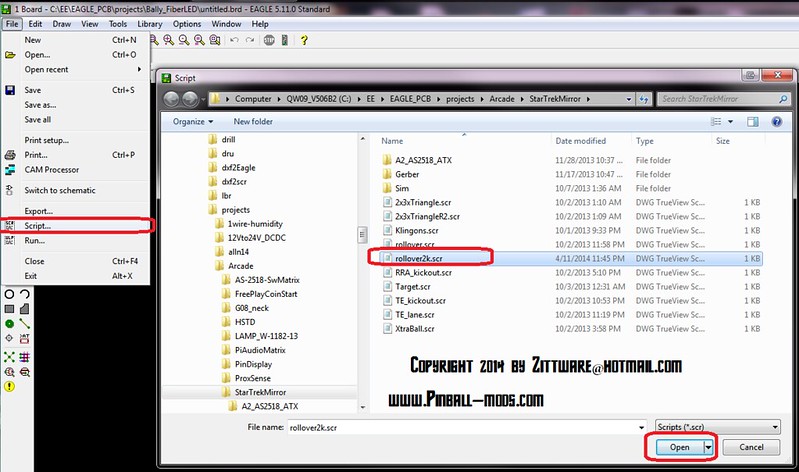

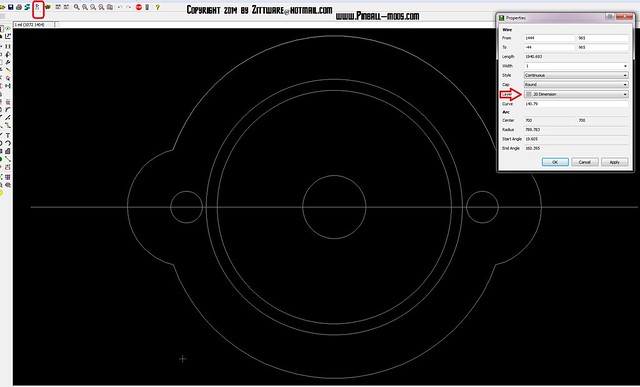

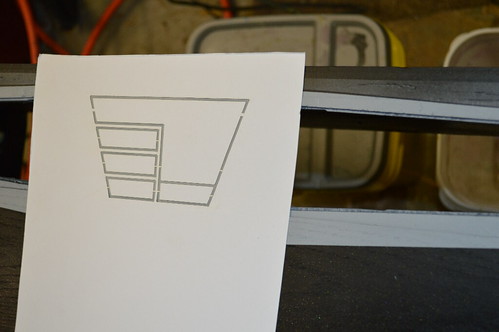

Using the great work by colosseumbuilders.com; I recreated the Enterprise’s impulse engines in CAD using the following as a guideline:

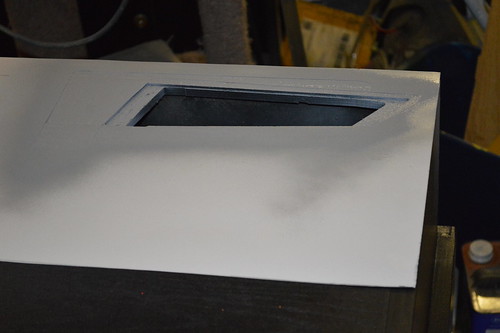

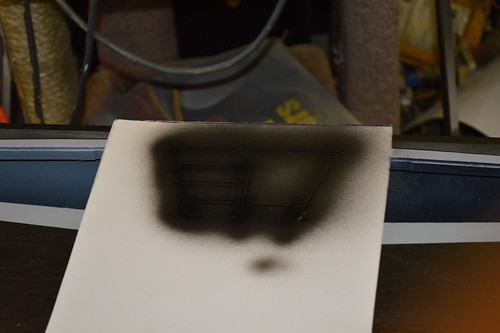

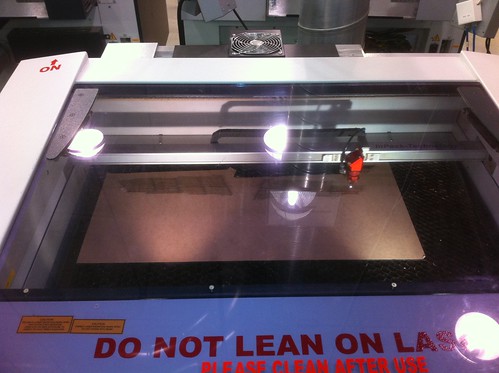

The resultant CAD file yielded the following rendering of the DXF file. In order to practice for the upcoming Playfeild CNC work; I wanted to practice with by CNCing out these vent holes in the Russian Plywood. Ken and I went to Techshop.ws this past Saturday and CNCed the back vents:

Once I got home; Saturday night I began re-assembling the head:

Then I lightly sanded and vacuumed the inside of the head to prep it for interior paint:

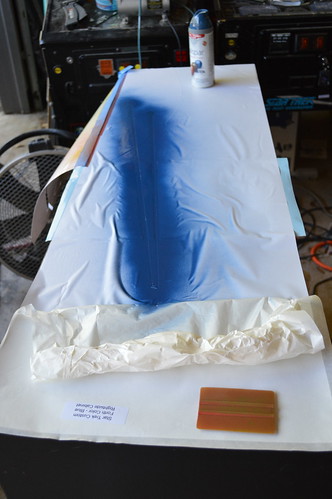

This time I decided to paint the inside prior to staining the outside; so:

After the interior dried; I needed to replace the Veneer which I removed during the deconstruction phase.

I thought about going to woodcraft to get it; but really; I didn’t want to drive 30minutes in traffic… so I opted to get the iron-on type from Lowes. It comes in a roll; and you melt the glue with an iron.

The smaller roll of veneer was on clearance; so I opted for it… but turned out to be a hair short. I filled the seams with Plastic Wood filler so the seams wouldn’t be visible on the back without a close inspection.

Not sure what I’m going to do about the small section… worst case I’ll apply a patch after-the-fact.

After some lite sanding with the orbital sander the back and the head was ready for the Black Dye:

followed by the Black Stain:

Even the bottom didn’t escape the black of space…

The plan is to let the Stain/Dye cure overnight. Then I’ll begin to spray the Polycrlic Satin clear coat over the stain to seal the wood and prep is for future Stenciling.

My head did not come with any of the metal trays for the displays… if anyone is parting out a early 80s Bally Solid State machine… I’d very much appreciate the opportunity to obtain these trays for my Nixie tube displays. Please post a comment or email me. Thanks!